- Home

- About Us

- Products Products

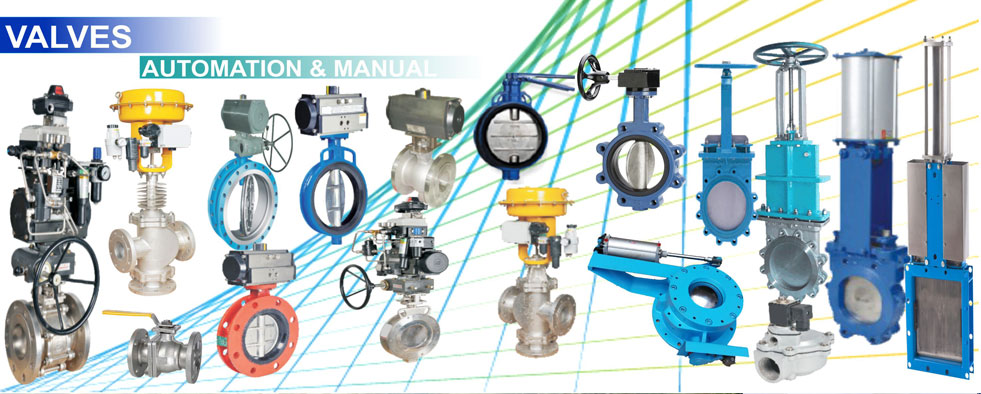

- Bulk Material Handling & Valves

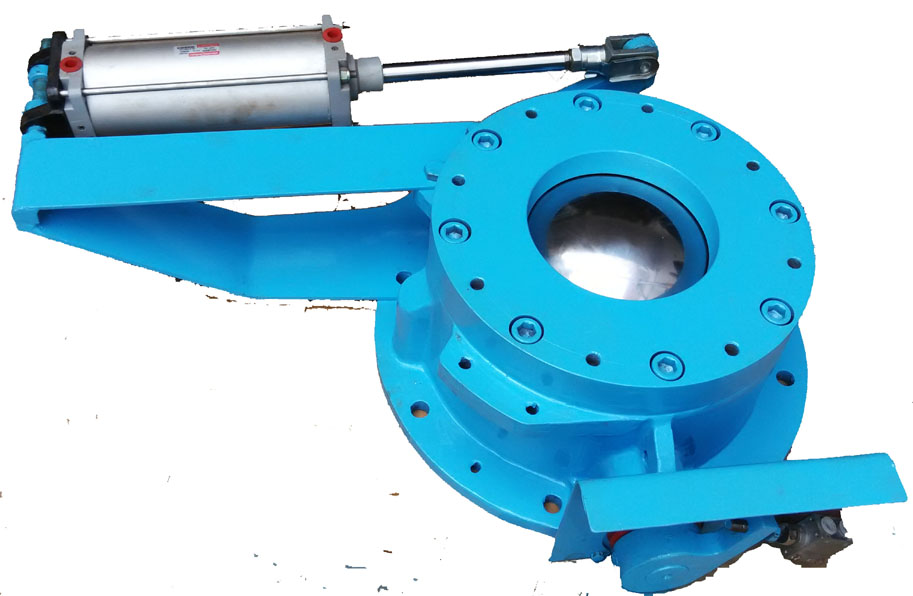

- Knife Edge Gate Valve

- Isolation Valves

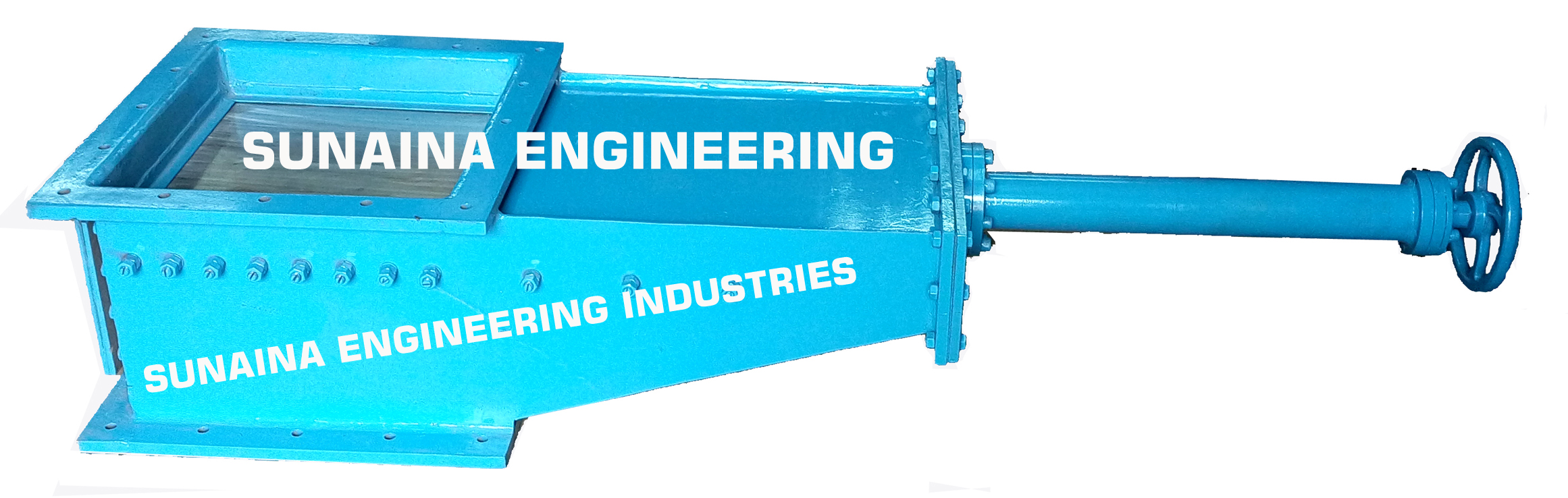

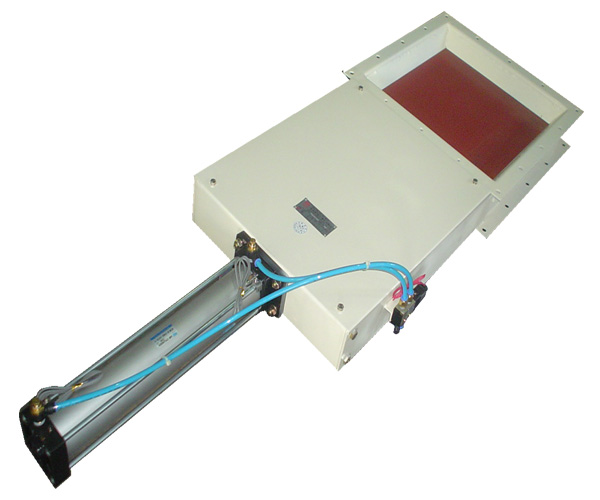

- Slide Gate Valves

- Blow Poppet Valve

- Non Return Valve

- Butter Fly Valve

- Double Disc Valve & Pressure Equalising Valve

- Segregating Valve

- Gate Valves

- Flanges

- Sleeve Coupling

- Ash Vessels & Ash Transmitter Vessels

- Ash Conditioner & Dust Conditioner

- Clinker Grinder

- Alloy C I Bends & Fittings

- Cast Basalt Bend & Ceramic Lined Fittings

- Alloy Castings & Ni Hard Cast Products

- Rotary Feeder & Rotary Airlock Valve

- Jet Pump Hydro Ejector

- Bag Filters & Dust Collectors

- Telescopic Chute

- Heavy Industrial Fabrication Or

- Conveyor Pulley

- Idlers & Roller For Belt Conveyors

- Vibrating Screen

- Screw Conveyor

- Material Handling Conveyor

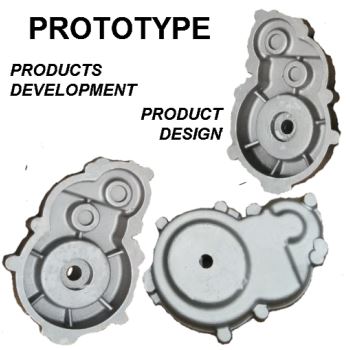

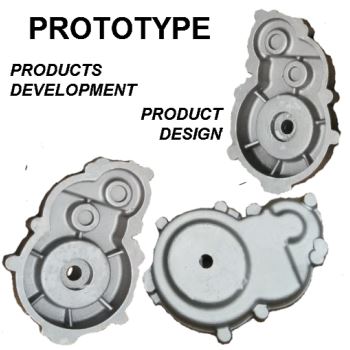

- Prototype

- Alloys Metal Casting

- Turbine Parts & Spares

- Customized Engineering

- Steam Turbine And Refabritation

- Patterns Making For Metal Casting

- Engineering & Industrial Fabrication

- Precision Vices

- Clamping Elements & Clamping Devices

- T BOLT

- Plain Washer

- T NUT

- Long Nut

- Extension Nut

- Tapped End Mould Clamp

- Stepped Strap Clamp

- Clamping Kit

- Strap Clamp

- c-washaer

- Step blocks

- Universal Strap Clamp

- Flange nut

- Mould Clamp with Stud OR T-Bolt

- Leveling jack

- Leveling Jack Heavi Duty

- Hight Block For Leveling Jack

- clamping Stud

- clamping stud Tapped

- U Type Mould Clamp

- Tool Room Accessories

- Die & Mould Springs & Accessories

- Precision Tools

- Mechanical Maintenances & Repairs Services

- Gimbal Ring

- Bulk Material Handling & Valves

- Quality

- Happening

- Newsletter

- Download Catalogue

- Contact Us